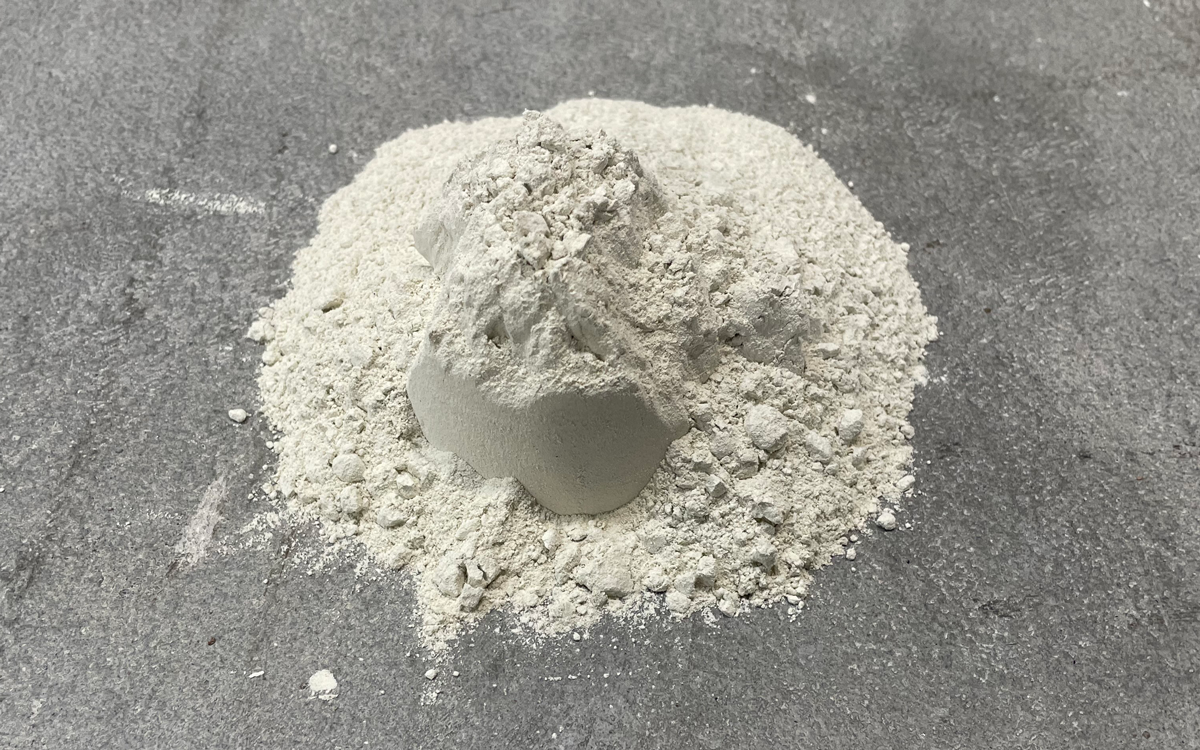

What is bentonite clay?

Bentonite is a very reactive clay that shrinks or swells markedly in response to the removal or addition of water.

Bentonite consists mainly of smectite minerals (swelling or expandable clay), commonly formed by the decomposition of volcanic ash or sometimes from other igneous or sedimentary rocks.

There are many applications for bentonite worldwide, including skincare, food production, clarifying wine, paper, kitty litter, etc. However, for this article, we will focus on industrial applications.

Selecting the right option of bentonite to use to suit your industrial application is not as simple as choosing the “best” bentonite. Working with an expert who has access to a range of suitable options will help you find the right product to suit the properties you need to achieve.

I will cover some of the critical properties of bentonite and review how this compares between different options. Next, I will discuss the cost implications between options and look at the risk/benefit opportunities when working with bentonite.

The critical properties we look at when considering the best option include;

Viscosity; the ability to create viscosity in water to assist cuttings to be transported under flow conditions

Filtration control; for borehole stability (when drilling or construction applications)

Gel Strength; for cuttings suspension during static periods

The bentonite's quality (which depends on the degree of surface contamination of the bentonite) dictates how well the bentonite will deliver these critical functions.

Viscosity

Viscosity is the most misunderstood property of bentonite. People perceive the faster bentonite mixes and builds viscosity - the better product. Understanding how viscosity is generated is essential. High solids loading will create viscosity due to mechanical friction, detrimental to drilling fluid properties. Good quality sodium bentonite will produce viscosity due to electrochemical interaction between individual platelets, contributing to the fluid's ability to transport drill cuttings.

Viscosity is helpful in drilling (to a point). Enhanced viscosity aids in hole cleaning and can reduce the overall cost when we are trying to build a fluid to a given viscosity. Quality bentonite modified to achieve a high yield for hole cleaning will be less effective at providing filtration control than high-quality unmodified bentonite with a lower viscosity yield.

As a result, before selecting the product with advice from your Technical Sales Manager, you need to understand what properties matter most to you. For example, if filtration control is the number one priority, high yield bentonite may not be the best solution.

Filtration control

If you are piling or building a diaphragm wall, filtration control for stability is likely to be your number one priority. Sodium bentonite with a low yield but good filtration control will provide the best option. If using high yield bentonite, you are likely to want to pair it with a PAC style polymer to aid in the filtration control properties.

Gel strength for suspension

One of the core properties of bentonite, in particular sodium bentonite, is to deliver gel strength to aid in the suspension of cuttings. This is relevant in a vertical drilling application but particularly when working horizontally, such as HDD or tunnelling.

Calcium versus sodium

For industrial purposes, two main classes of bentonite are recognised: calcium and sodium bentonite. However, the properties above vary significantly related to each.

Calcium bentonite

Calcium bentonite is widely available. However, the quality of these deposits varies widely. Some construction applications (such as filling a void) are likely only to need a very simple construction-grade bentonite. For example, good calcium bentonite may meet the requirements in a tunnelling job with low sand content, but these bentonites are usually modified to meet the required drilling fluid functions.

Sodium bentonite

There are minimal worldwide deposits of sodium bentonite and none in the South Pacific. The largest deposits of sodium bentonite are in Wyoming in the US. When needing better properties of bentonite for more challenging drilling applications, such as HDD and water well, sodium bentonite will deliver significantly better properties. It is more expensive per bag, but calcium bentonite (even when altered with polymers) cannot provide the same properties.

Both calcium bentonite and sodium bentonite expand through water absorption (hydration). Calcium bentonite will absorb up to 2.8 times its volume of freshwater. Sodium bentonite will absorb far more, up to 8 times its volume of freshwater, meaning you require less product to achieve the same or better results than when using calcium bentonite.

The property of swelling also makes sodium bentonite useful as a sealant since it provides a self-sealing, low permeability barrier. It is used to line the base of landfills, for example. In addition, various surface modifications to sodium bentonite improve some rheological properties or sealing performance in geoenvironmental applications, for example, the addition of polymers.

The classification as calcium or sodium bentonite is less important than how well the bentonite delivers the critical functions of viscosity, filtration control and gel strength in ways that are required to provide your specific outcome.

Bentonite is a product mined and bagged worldwide by several top manufacturers. The competitive market worldwide, means that the volume you would require to mix into 1,000L of water to use in industrial applications, could cost you between AUD$14 / NZD$15 and AUD$28 / NZD$30 depending on the properties required. However, because the properties of each product vary widely, the price per bag is often an unhelpful comparison, and likely to lead to selecting an option that may not be optimal or even cost-effective for your project. Often comparing different grades of bentonite against each other without technical advice is difficult, due to different volumes being required to generate similar properties. Beyond that, extra volume can create other negative characteristics that are easy to underestimate when pricing up fluid in isolation.

The price of a bag of a similar grade of bentonite, between one supplier and another, could be as little as $1 or $2. Historically, because of a lack of understanding and competitive availability - drilling fluid programmes often simply used more bentonite to improve properties. As a result, it is common for contractors to perceive more bentonite as cheaper than using polymers or lubricants with specific properties, to deliver better (and more cost-effective) outcomes.

Any contractor needs to ensure that they get good value from the products they buy. However, when it comes to drilling fluids and bentonite, the cost difference for equivalent quality products between one supplier and another will be small.

When deciding on a product to use, finding a supplier who can provide you with technical support at design, project execution, and review is often worth more than the product itself.

Blick has been a supplier to the drilling industry in Australasia for over 50 years. Blick and M-I SWACO work as a partnership for water-based drilling fluids across Australia, New Zealand, and the Pacific. They excel in support and advice.

Contact us today if you’re looking at optimising your performance and reducing costs through engineered fluid solutions. Our Australia team is available on +61 3 9068 5688 (Melbourne) or +61 8 6271 3575 (Perth) and New Zealand on +64 7 849 2366.